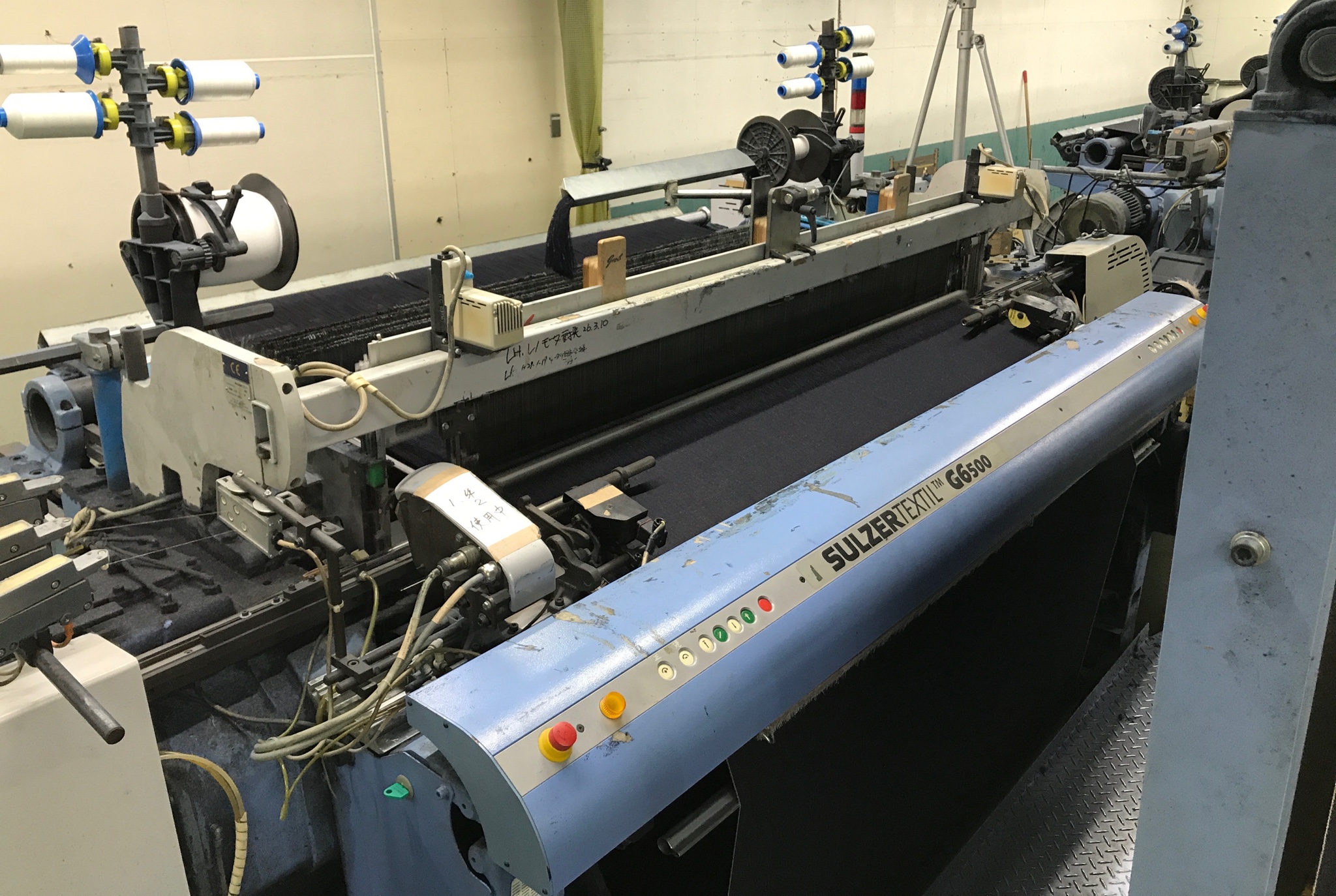

The Manufacturing Process

Using both modern electronically-controlled looms and old machine-type shuttle looms, we weave various kinds of denim.

We’re proud of providing underlying support for glamorous fashions by engaging in the low-profile work of creating high-quality materials while working closely with the loom and threads.